In the realm of precision machining, Delos Linear Scale DRO Kits have become an indispensable tool for milling machines, significantly enhancing both accuracy and operational convenience. These digital readout systems, such as the popular Linear Scale KA300 and Sino Linear Scale, play a pivotal role in modern machining processes.

**Key Applications of Linear Scale DRO Kits**

1. **Precision Improvement**:

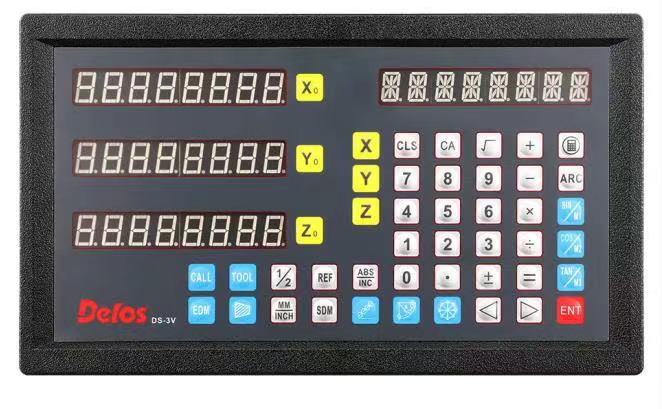

Delos DRO Kits, including the Delos Linear Scale, offer high-precision position data by reading the linear scale, enabling exact measurement of tool or workpiece movement along the X, Y, and Z axes. This capability allows operators to make precise adjustments, minimizing errors inherent in traditional mechanical readouts.

2. **User-Friendly Operation**:

The digital readout provides a clear display of the worktable's position changes, simplifying the operation by eliminating the need for manual reading of mechanical dials, thereby increasing work efficiency.

3. **Consistency in Repetitive Tasks**:

Delos Linear Scale DRO Kits allow operators to record specific position data, facilitating quick return to the same position during repetitive machining tasks, ensuring consistency, especially in batch production.

4. **Reduction of Human Error**:

Traditional mechanical readings often depend on human judgment, which can lead to errors. The electronic display of Delos DRO Kits reduces such errors, ensuring uniformity and reliability in machining results.

5. **Complex Machining Capabilities**:

For tasks requiring precise control and multi-axis coordination, Delos Linear Scale DRO Kits help operators manage each step more effectively, enhancing the quality of complex part machining.

**Key Considerations When Purchasing Linear Scale DRO Kits**

When purchasing Linear Scale DRO Kits, such as the Delos or Sino models, several factors must be considered to ensure they meet your machining needs and are compatible with your milling machines:

1. **Resolution**: T

he resolution of the DRO system is crucial, determining the smallest detectable displacement. A 1-micron resolution is ideal for high-precision tasks, whereas lower resolutions suffice for general machining.

2. **Measurement Range**:

The linear scale's measurement length must match the machine's travel range, ensuring accurate measurement throughout the machine's entire motion.

3. **Compatibility**:

The DRO system must be electrically compatible with the machine's control system, including power voltage and signal output (TTL, RS-422, etc.). Any mismatch may require additional interfaces or converters.

4. **Environmental Suitability**:

Consider the working environment of your milling machine. The DRO kit, such as the Sino Linear Scale, should have adequate protection against coolant, oil, and metal chips, with a suitable IP rating to ensure reliable operation.

5. **Installation**:

Ensure that the chosen DRO kit can be properly installed on your machine, considering space constraints and mounting requirements.

6. **Brand and After-Sales Support**:

Opting for well-known brands like Delos ensures better product quality and robust after-sales support, including installation guidance and technical assistance.

**Importance of Matching the DRO System with the Machine**

The successful integration of a DRO kit with a milling machine requires mechanical, electrical, and interface compatibility. The length of the linear scale must suit the machine’s travel, and the system’s interface should align with the operator's workflow and the machine's control system.

#Linear scale DRO kits#digital readout#Delos DRO kits#Delos linear scale#Linear scake KA300#Sino linear scale#www.metalcnctools.com

Post time: Aug-29-2024