In the world of precision machining, efficiency and accuracy are paramount. One tool that has revolutionized how machinists operate milling machines is the **Magnetic Working Table**. Often referred to as **Magnetic Beds** or **Magnetic Chuckers**, these devices are more than just convenient—they are a game-changer in the machining industry.

**Boosting Efficiency with Magnetic Working Tables**

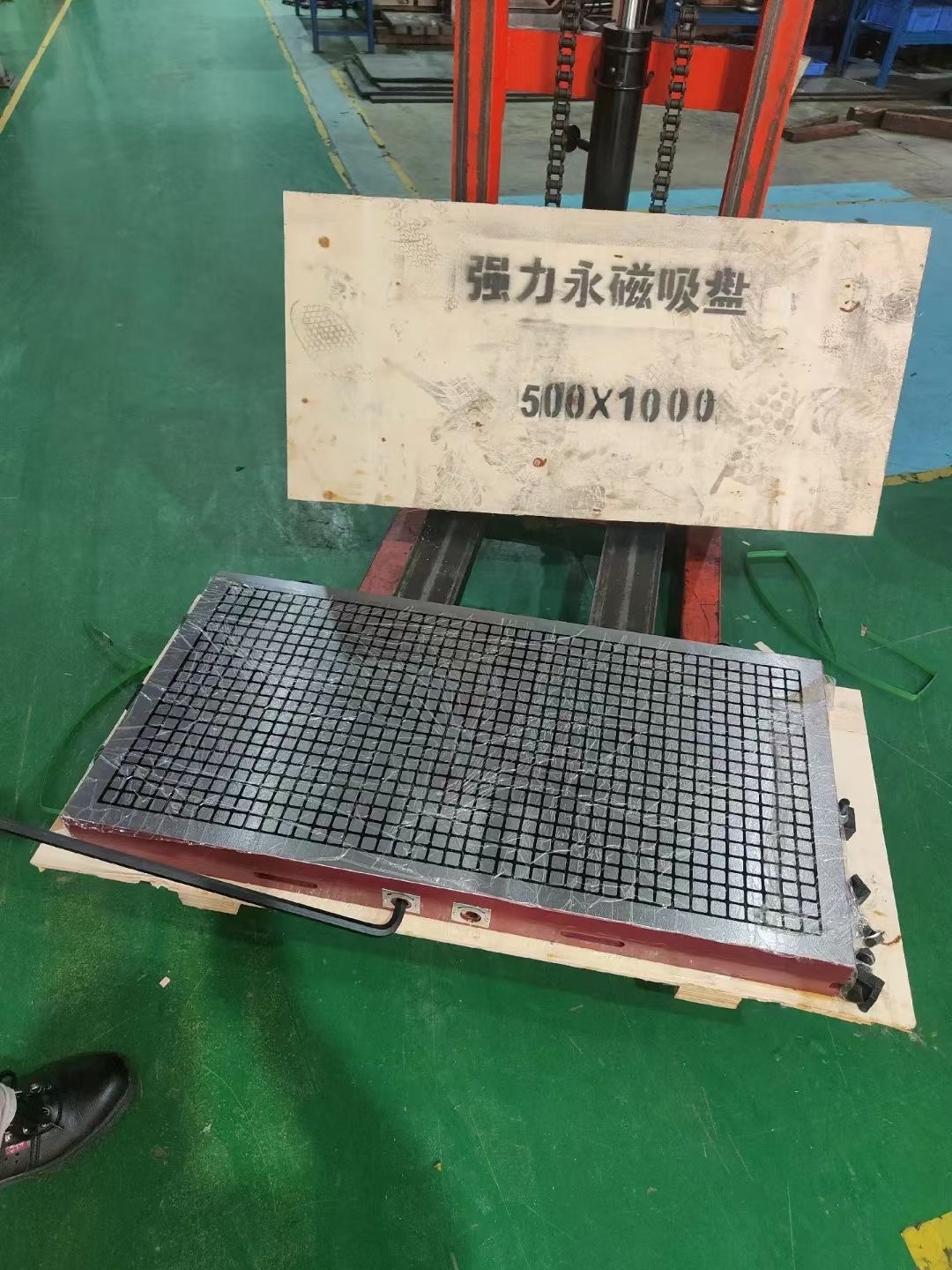

Magnetic working tables are designed to enhance the efficiency of milling machines by securely holding workpieces in place. This secure holding is achieved through strong magnetic forces that keep the workpiece steady, minimizing vibrations and shifts during operation. Here’s how they contribute to higher efficiency:

1. **Increased Stability and Accuracy**: By firmly securing the workpiece, magnetic working tables reduce the risk of movement during machining, resulting in more precise and consistent cuts. This stability translates into higher quality finished products and less need for rework.

2. **Faster Setup Times**: Unlike traditional clamping systems that require manual adjustment and alignment, magnetic tables allow for quick and easy setup. Machinists can rapidly place and secure workpieces, significantly reducing setup time and increasing overall productivity.

3. **Versatility in Handling Various Sizes and Shapes**: Magnetic working tables, especially those with adjustable magnetic force, can accommodate a wide range of workpiece sizes and shapes. This adaptability makes them ideal for diverse machining tasks and different material types.

**Impact of Magnetic Strength, Size, and Material**

The performance and longevity of a magnetic working table are significantly influenced by its magnetic strength, size, and material:

- **Magnetic Strength**: The strength of the magnet determines how securely the workpiece is held. Adequate magnetic strength ensures that even heavy or larger workpieces are firmly in place, preventing any slippage during machining.

- **Size and Shape**: The dimensions of the magnetic working table must match the size of the workpieces being machined. An appropriately sized table provides a better magnetic hold and more even distribution of forces. Additionally, the shape of the table can affect how well it conforms to different workpiece geometries.

- **Material**: The durability and longevity of the magnetic working table are influenced by the quality of the materials used. High-quality materials resist wear and corrosion, ensuring a longer service life and consistent performance.

**Maintenance and Care**

Proper maintenance is essential for ensuring the longevity and effectiveness of magnetic working tables:

1. **Regular Cleaning**: Keep the magnetic surface clean and free of debris. Use a soft cloth and appropriate cleaning solutions to remove dust, metal shavings, and other contaminants that could affect magnetic performance.

2. **Inspect for Damage**: Regularly check the table for any signs of wear or damage. Address any issues promptly to avoid affecting the table’s performance or the quality of your work.

3. **Proper Storage**: When not in use, store the magnetic working table in a clean, dry environment to prevent rust and damage. Ensure that it is placed in a position where it won’t be subjected to impacts or other forms of physical stress.

4. **Check Magnetic Force**: Periodically test the magnetic strength to ensure it remains within the required specifications. Adjustments might be necessary based on the workpieces being handled.

In summary, magnetic working tables are indispensable tools that enhance efficiency, accuracy, and productivity in machining operations. By understanding and maintaining the key aspects of magnetic strength, size, and material, and by following proper maintenance practices, machinists can ensure that their magnetic working tables continue to perform optimally, supporting high-quality manufacturing and machining processes.

#Magnetic bed#Magnetic working table#Magnetic chucker#www.metalcnctools.com

Post time: Aug-14-2024