Lathe chuck jaws are the clamping mechanisms located within a lathe chuck, designed to secure the workpiece in place. They come in various configurations, with 3-jaw and 4-jaw chucks being the most common. The choice between them depends on the specific machining requirements and the shape of the workpiece.

Differences Between 3-Jaw and 4-Jaw Lathe Chucks:

The primary difference between a 3-jaw and a 4-jaw lathe chuck lies in their design and functionality:

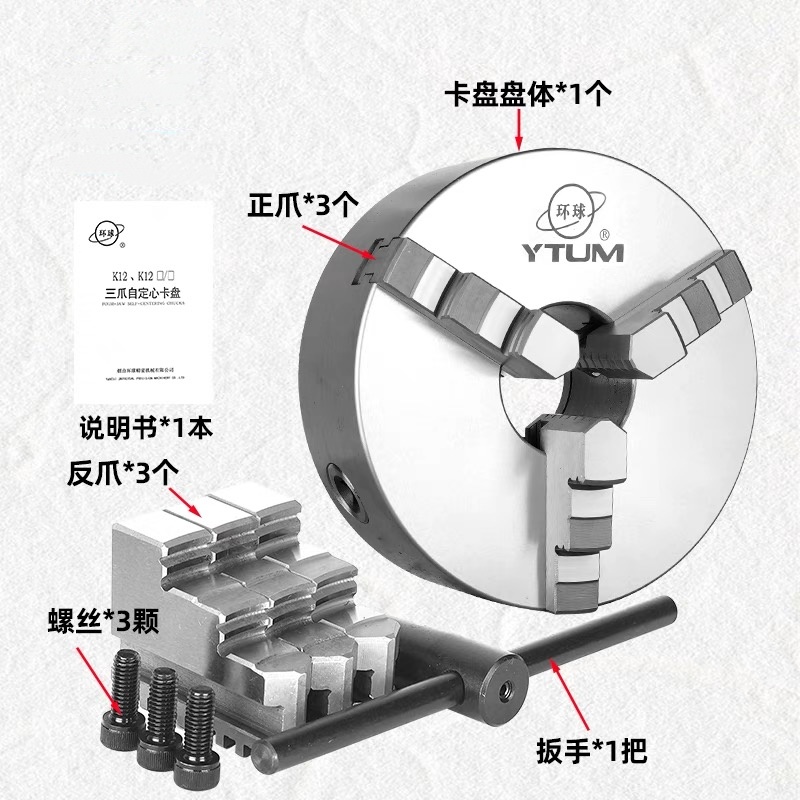

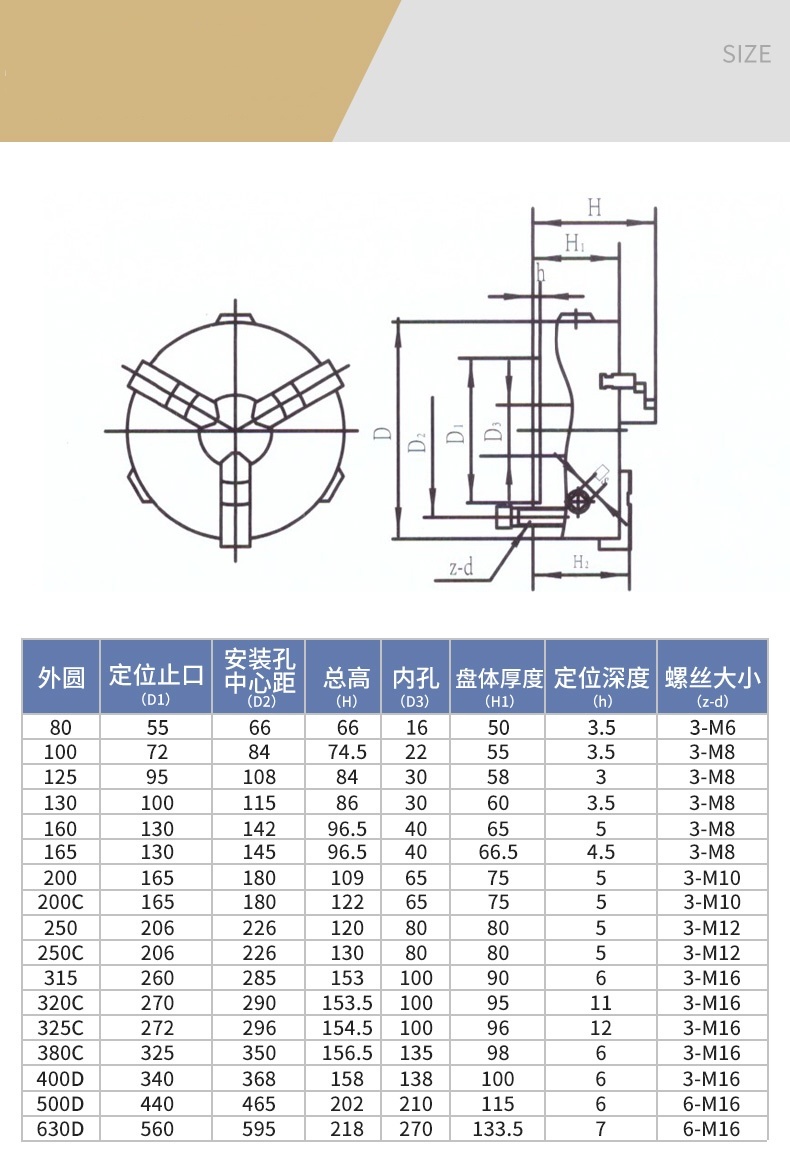

3-Jaw Lathe Chuck: This type is widely used due to its ability to grip cylindrical objects quickly and uniformly. The jaws move simultaneously when the chuck is tightened, making it ideal for repetitive tasks where speed and efficiency are critical. Common sizes include 8-inch and 10-inch chucks.

4-Jaw Lathe Chuck: Unlike the 3-jaw chuck, a 4-jaw chuck allows for independent adjustment of each jaw. This feature is beneficial for holding irregularly shaped workpieces or for precise centering. It requires more setup time but offers greater flexibility and precision in machining operations.

Additional Chuck Options

For specialized applications, lathe users may also consider 6-jaw or even larger 8-inch and 10-inch chucks, depending on the size and type of workpiece. Moreover, CNC lathe soft jaws and Buck Chuck soft jaws are excellent options for those needing a custom grip on delicate materials or unique shapes.

Conclusion

Selecting the right lathe chuck is essential for achieving high-quality machining results. Whether opting for a 3-jaw or 4-jaw configuration, understanding the differences and capabilities of each type can significantly enhance productivity. For more information on wholesale lathe chuck options and high-quality lathe chuck parts, visit our factory website.

lathe chuck#collet chuck for lathe#4 jaw lathe chuck#3 jaw lathe chuck#6 jaw lathe chuck#8 inch lathe chuck#10 inch lathe chuck#www.metalcnctools.com

Post time: Sep-27-2024